A crucial switch

A first investment in an ACM-NT Compact system will provide immediate access to first-class automated cut-up. It uses the same modules as a full-blown ACM-NT solution and both systems, therefore, have the same performance. “ACM-NT Compact is an ideal platform to make the crucial switch from processing whole chicken to cut-up products. Processors of any type and size can benefit from this system. If the market grows or the demand becomes more specific, the update is easy. The necessary modules are simply added to the existing set-up,” says Marco Solleveld.

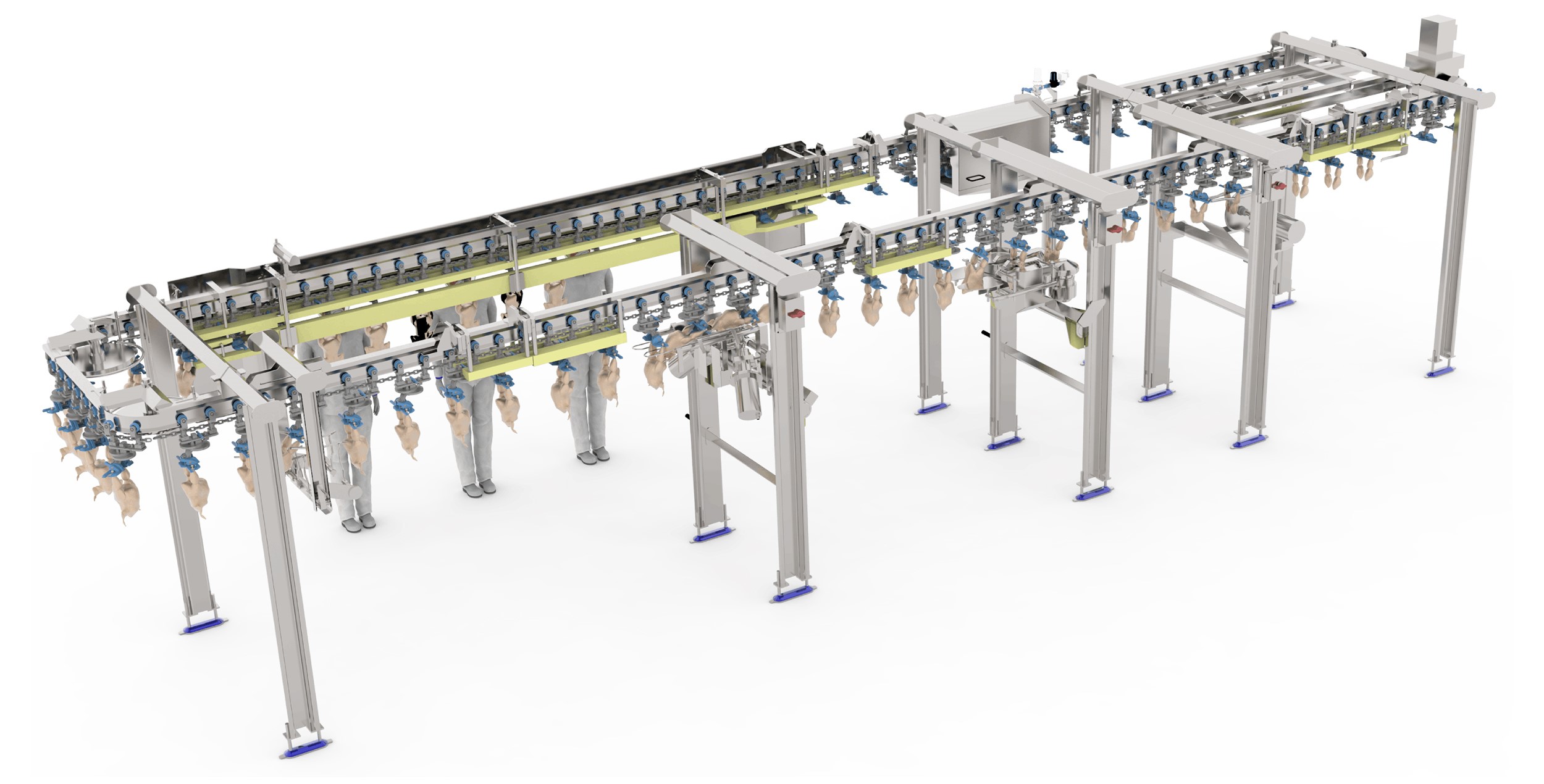

ACM-NT Compact takes into account the available space in a processing plant. The system offers three standardized overhead steel frames, all with a small footprint. Even when space in the factory is limited, the ACM-NT Compact will still fit in.

Always fit in

By investing gradually over time, the modular system can grow from the first basic cuts to a powerful in-line cut-up solution, with fully flexible capacity up to 6,500 bph, achieving multiple cuts intelligently and simultaneously, without manual interference.

It will also be possible to automate the shackling of the products by transferring them selectively in the overhead conveyor, reducing even more the need for manual labor. Added Innova software will give the system more intelligence, allowing each chicken to be cut up according to need and possibility and monitoring production in real-time.

Marco Solleveld concludes: “ACM-NT Compact is a smart investment as it offers the best of both worlds. It meets the demands of today with a small footprint, and is also ready for the future."